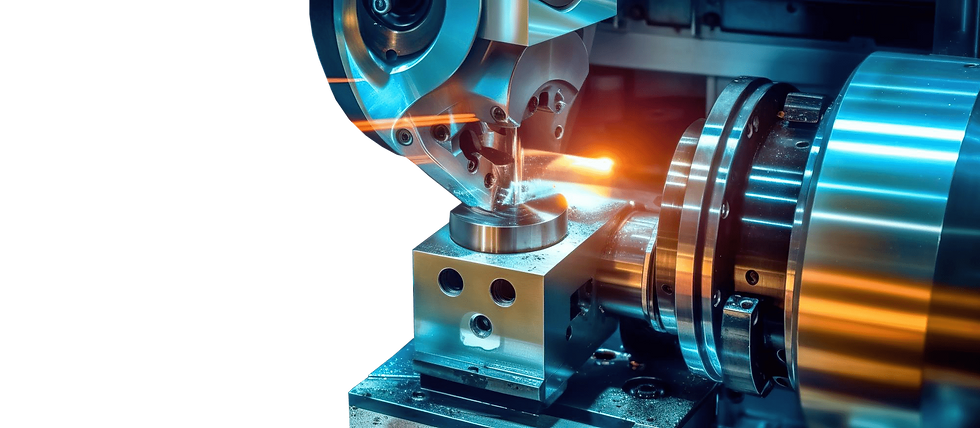

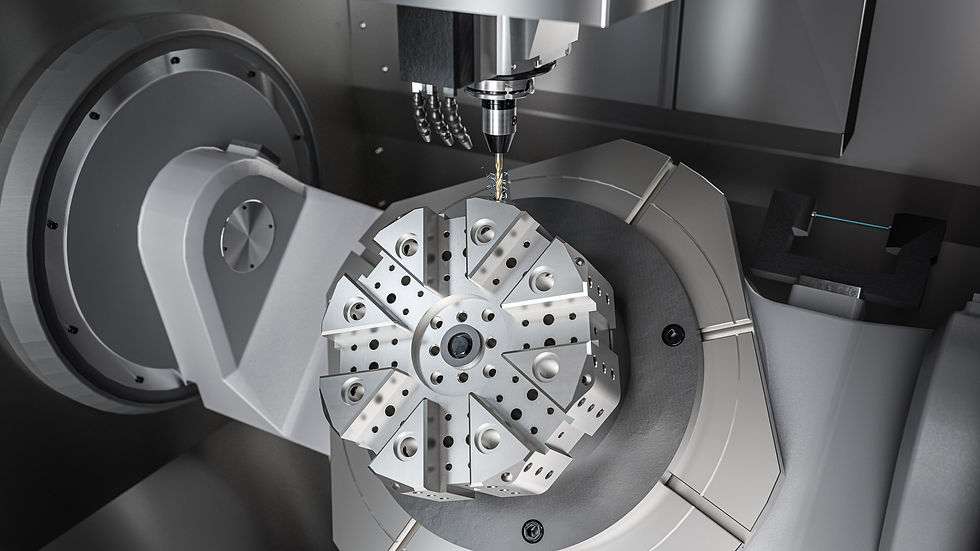

CNC (Computer Numerical Control) turning is a specialized machining technique that involves the use of computer-controlled machinery to create precision components and parts from various materials. CNC turning plays a critical role in modern manufacturing and is used in industries such as aerospace, automotive, medical, and more. A CNC Turning course is designed to provide individuals with the knowledge and skills required to operate and program CNC lathes effectively.

Description

What You'll Learn

CNC Turning

Course Details

Course Level

Beginner

Duration

5 Months

Lectures

32 Lectures

Mode

Offline

COURSE NAME

CNC CUSTOM MACRO PROGRAMMING

COURSE LEVEL - CUSTOM PROGRAMMER

COURSE OVERVIEW

Macros give the programmer the ability to perform arithmetic and comparison functions within a CNC program.

Values from macro statements can be passed to the CNC program by using parametric variables.

Macros may be used for probe functions and for part outlines where the part can be defined by an arithmetic formula.

At the conclusion of the course students will be able to develop CNC custom programs to reduce cycle times, increase automation and improve efficiency of programming.

Even the existing CNC part programs can be moderated to macro programs efficiently beyond the limitations of existing G codes.

DURATION - 4 Days

COURSE CO-ORDINATOR

Mr. Dharmender Singh (B.E. Mech., M.E. Production)

Mr. Dharmendra Patel (B.Tech. Production)

COURSE TOPICS

Introduction To Part Programming

Introduction To Macro Programming

Macro Programming Tools

Macro Structure

Data Setting

System Variables And Expressions

Assigning Variables

Macro Arithmetic Commands

Tool Offset Variables

Decisions And Loops

Macro Call

External Output Commands

Alarms And Timers

Parametric Programming

Custom Canned Cycles

Probing With Macro

Interfacing Macro Commands With Physical I/O

Programmable Data Input

Macro Program Simulation On PC In 3D Environment

WHO SHOULD ATTEND

CNC Machine Setters

CNC Programmers

CAD/CAM Engineers

Production Engineers

CNC Machine Maintenance Engineers

Industrial Automation Engineers

Machine Manufacturers

Manufacturing Engineers

PREREQUISITES

CNC Turning Programming And Operating : Fanuc Entry Level

(Course Code : CNC1501)

CNC Milling Programming And Operating : Fanuc Entry Level

(Course Code : CNC1502)

CNC Turning Programming And Operating : Siemens Entry Level

(Course Code : CNC1503)

CNC Milling Programming And Operating : Siemens Entry Level

(Course Code : CNC1504)

CNC Programming And Operating : Expert Programmer

(Course Code : CNC1505)

ALLIED COURSES

Machine Drawing And Blue Print Reading (Course Code : EG1503)

AutoCAD Essentials (Course Code : ACAD1501)

COURSE NAME

CNC TURNING OPERATING AND PROGRAMMING > FANUC ESSENTIALS

CONTROLLER - INDUSTRIAL FANUC CONTROL

COURSE LEVEL - INTRODUCTORY

COURSE OVERVIEW

The modern manufacturing machines utilise the CNC technology known for their accuracy and precision without much human intervention.

This course is intended for the users willing to start their career in the manufacturing sectors working on CNC Turning Machines.

Expert programmers have developed this course based on the industrial requirements.

CNC programs and exercises for practice cover all the most commonly used G and M codes.

The Use of computers during training program help the students to work in 3D environment using specialized software and simulate tool’s cutting motions to verify their programs.

This course is equally prescribed for the technical or non-technical students to have a complete understanding of CNC technology.

DURATION - 10 Days (40 Hrs)

COURSE CO-ORDINATOR

Mr. Dharmender Singh (B.E. Mech., M.E. Production)

COURSE TOPICS

1. INTRODUCTION

What is a CNC control?

How FANUC CNC control is different from other CNC controls

Introduction to FANUC CNC control screen layout

Explanation of Coordinate system

Meanings of WCS, MCS and reference point

Right hand rule for Lathe Axis designation

Fundamentals of 2 Axis, 3 axis and 5 axis CNC Turning machine

Fundamental Difference between Turning and TurnMill

Advantage of dual spindle CNC Turning

Description of Operating Modes

Manual control modes : JOG/HANDLE/MDA Modes

Description of working in AUTO Mode

Description of feed override and spindle speed override

2.CNC TURNING MACHINE SETUP AND MACHINING OPERATIONS

What is a Lathe?

How the Lathe Machine Works

Machine Components and Their Locations

List of CNC Turning Machine Operations

Tool selection Criterion

Tool Holding In Tool Turret

Nomenclature of Tools and Inserts

Work Holding Methods

Introduction of Fixtures

What is MCS and WCS in CNC Terms

Programming and Setting the Job Zero

Demonstration of Different Machine Components on CNC Lathe

Introduction to Simulation Software

3. PART PROGRAM CREATION AND EDITING METHODS

Explanation of Elements of Program Header

Program Units Selection

Tool Selection and Calling Offsets

Spindle Speed Selection and Direction of Rotation

Concept of Constant RPM (G97) and Constant Surface Speed (G96)

Setting The Cutting Feed Rate (G98 and G99)

Linear Tool Path Programming (G00 and G01)

Simple Programs for Facing and Chamfering

Simple Programs for Step Turning and Taper Turning

Circular Tool Path Programming (G02 and G03)

Creating Fillets and Rounds on Workpiece

Introduction to Simple Program Cycles

Use of Turning and Facing Cycles

Creating Forward and Reverse Tapers

Grooving Cycle (G75) for OD /ID and Face Grooving

Incorporating Optional Stop and Program Skip Commands

Necessary Elements of Program Footer

Different Methods / Codes to End a Program

Computer Simulation Practicals to Use a Machine Panel

Program Creation, Editing and Verification

Machining Practice on Real Time Industrial CNC Turning Machine

4.ADVANCE PROGRAMMING TECHNIQUES FOR TURNING JOBS

Introduction to Multiple Repetitive Programming Cycles

Use and Application of Multiple Turning Cycle (G71)

Use and Application of Multiple Facing Cycle (G72)

Use and Application of Profile Repeating Cycle (G73)

Finishing Cycle (G70)

Strategy Planning For Forged and Cast Components

Criteria for Feed, Speed and Depth of Cut Selection

Introduction to Insert Grades for Hard Materials

Industry Case Studies

Industry Based Exercises and Questionnaire for Practice

Verification and Simulation of Advance Programs

Training Videos by World Class CNC Machine Manufacturers and Users

Machine Practicals for Cutting Job Using Advance Programming Codes

5.CUTTING THREADS ON CNC TURNING MACHINE

Theory Classes on Thread Profiles and Thread Nomenclature

Introduction to ISO, British and American Thread Standards

Threading Insert Types and Selection Criteria

Introduction to Thread Cutting Strategy For Accurate Profile Machining

Cutting Straight Threads

Concept of Single Start Threads

Cutting Right Hand Threads

Threading Codes G92 and G33

Thread Cutting Practicals on Simulation Software

Setting Machine for OD and ID Threading

Real Time Machining Practical on Industrial CNC Turning Machine

6.INTERNAL (ID) MACHINING OPERATIONS

Introduction to Drilling Boring and Tapping Operations

Standard Drilling Operation Using G81

Peck Drilling - G74

Straight Boring

Taper Boring

ID Chamfer and Rounds

Cutting Internal Grooves

Programs for Deep Grooves - Safety Precautions

Machining Cycles For Straight and Taper Boring

Creating Program for Drilling, Boring and Threading

Offline Practical on Desktop PC and 3D Simulation

Machining a Workpiece on Industrial CNC Turning Machine

WHO SHOULD ATTEND

X, XII Pass

Graduates / Under Graduates

ITI, Diploma and B.Tech. Students

CAD Operators

Product Designers

Machine Operators

Maintenance Engineers

Production Engineers

PREREQUISITES - None

ALLIED COURSES

Machine Drawing And Blue Print Reading (Course Code : EG1503)

AutoCAD Essentials (Course Code : ACAD1501)

CNC MILLING – Operating and Programming (Course Code : CNC1502)

COURSE NAME

CNC TURNING OPERATING AND PROGRAMMING > FANUC ESSENTIALS

CONTROLLER - INDUSTRIAL FANUC CONTROL

COURSE LEVEL - INTRODUCTORY

COURSE OVERVIEW

The modern manufacturing machines utilise the CNC technology known for their accuracy and precision without much human intervention.

This course is intended for the users willing to start their career in the manufacturing sectors working on CNC Turning Machines.

Expert programmers have developed this course based on the industrial requirements.

CNC programs and exercises for practice cover all the most commonly used G and M codes.

The Use of computers during training program help the students to work in 3D environment using specialized software and simulate tool’s cutting motions to verify their programs.

This course is equally prescribed for the technical or non-technical students to have a complete understanding of CNC technology.

DURATION - 10 Days (40 Hrs)

COURSE CO-ORDINATOR

Mr. Dharmender Singh (B.E. Mech., M.E. Production)

COURSE TOPICS

1. INTRODUCTION

What is a CNC control?

How FANUC CNC control is different from other CNC controls

Introduction to FANUC CNC control screen layout

Explanation of Coordinate system

Meanings of WCS, MCS and reference point

Right hand rule for Lathe Axis designation

Fundamentals of 2 Axis, 3 axis and 5 axis CNC Turning machine

Fundamental Difference between Turning and TurnMill

Advantage of dual spindle CNC Turning

Description of Operating Modes

Manual control modes : JOG/HANDLE/MDA Modes

Description of working in AUTO Mode

Description of feed override and spindle speed override

2.CNC TURNING MACHINE SETUP AND MACHINING OPERATIONS

What is a Lathe?

How the Lathe Machine Works

Machine Components and Their Locations

List of CNC Turning Machine Operations

Tool selection Criterion

Tool Holding In Tool Turret

Nomenclature of Tools and Inserts

Work Holding Methods

Introduction of Fixtures

What is MCS and WCS in CNC Terms

Programming and Setting the Job Zero

Demonstration of Different Machine Components on CNC Lathe

Introduction to Simulation Software

3. PART PROGRAM CREATION AND EDITING METHODS

Explanation of Elements of Program Header

Program Units Selection

Tool Selection and Calling Offsets

Spindle Speed Selection and Direction of Rotation

Concept of Constant RPM (G97) and Constant Surface Speed (G96)

Setting The Cutting Feed Rate (G98 and G99)

Linear Tool Path Programming (G00 and G01)

Simple Programs for Facing and Chamfering

Simple Programs for Step Turning and Taper Turning

Circular Tool Path Programming (G02 and G03)

Creating Fillets and Rounds on Workpiece

Introduction to Simple Program Cycles

Use of Turning and Facing Cycles

Creating Forward and Reverse Tapers

Grooving Cycle (G75) for OD /ID and Face Grooving

Incorporating Optional Stop and Program Skip Commands

Necessary Elements of Program Footer

Different Methods / Codes to End a Program

Computer Simulation Practicals to Use a Machine Panel

Program Creation, Editing and Verification

Machining Practice on Real Time Industrial CNC Turning Machine

4.ADVANCE PROGRAMMING TECHNIQUES FOR TURNING JOBS

Introduction to Multiple Repetitive Programming Cycles

Use and Application of Multiple Turning Cycle (G71)

Use and Application of Multiple Facing Cycle (G72)

Use and Application of Profile Repeating Cycle (G73)

Finishing Cycle (G70)

Strategy Planning For Forged and Cast Components

Criteria for Feed, Speed and Depth of Cut Selection

Introduction to Insert Grades for Hard Materials

Industry Case Studies

Industry Based Exercises and Questionnaire for Practice

Verification and Simulation of Advance Programs

Training Videos by World Class CNC Machine Manufacturers and Users

Machine Practicals for Cutting Job Using Advance Programming Codes

5.CUTTING THREADS ON CNC TURNING MACHINE

Theory Classes on Thread Profiles and Thread Nomenclature

Introduction to ISO, British and American Thread Standards

Threading Insert Types and Selection Criteria

Introduction to Thread Cutting Strategy For Accurate Profile Machining

Cutting Straight Threads

Concept of Single Start Threads

Cutting Right Hand Threads

Threading Codes G92 and G33

Thread Cutting Practicals on Simulation Software

Setting Machine for OD and ID Threading

Real Time Machining Practical on Industrial CNC Turning Machine

6.INTERNAL (ID) MACHINING OPERATIONS

Introduction to Drilling Boring and Tapping Operations

Standard Drilling Operation Using G81

Peck Drilling - G74

Straight Boring

Taper Boring

ID Chamfer and Rounds

Cutting Internal Grooves

Programs for Deep Grooves - Safety Precautions

Machining Cycles For Straight and Taper Boring

Creating Program for Drilling, Boring and Threading

Offline Practical on Desktop PC and 3D Simulation

Machining a Workpiece on Industrial CNC Turning Machine

WHO SHOULD ATTEND

X, XII Pass

Graduates / Under Graduates

ITI, Diploma and B.Tech. Students

CAD Operators

Product Designers

Machine Operators

Maintenance Engineers

Production Engineers

PREREQUISITES - None

ALLIED COURSES

Machine Drawing And Blue Print Reading (Course Code : EG1503)

AutoCAD Essentials (Course Code : ACAD1501)

CNC MILLING – Operating and Programming (Course Code : CNC1502)

COURSE NAME

CNC ADVANCED PROGRAMMING

CONTROLLER - INDUSTRIAL FANUC/SINUMERIK CONTROL

COURSE LEVEL - EXPERT PROGRAMMER

COURSE OVERVIEW

The manufacturing sector in general and metalworking is expanding every day with the introduction of new materials, tools and processes.

The CNC machine setters and programmers are finding difficulties in facing these day to day challenges.

By joining this advanced course in CNC training, the experienced programmers will gain the most current industrial level expertise to create smart programs using the advanced techniques.

Theory lectures are prepared on the topics like CNC Tooling and Insert types for various machining operations after deep research.

Workshop calculations, selection of Feed, Speed and depth of cut, technical working drawing reading are the key areas where emphasis is focused the most for those who lack understanding in spite of long experience in manufacturing industry.

In-depth information is exchanged in a customised plan to benefit the most from our comprehensive expertise in CNC training.

After this new level of expertise in CNC programming the user can handle difficult CNC machining problems with greater confidence.

DURATION - 10 Days

COURSE CO-ORDINATOR

Mr. Dharmender Singh (B.E. Mech., M.E. Production)

Mr. Dharmendra Patel (B.Tech.Production)

COURSE TOPICS

1. CNC COORDINATE SYSTEM

Machine Coordinate System (MCS)

Work Coordinate System (WCS)

Local Coordinate System (LCS)

2. TOOL OFFSETS

Four Different Offset Methods

Changing Work Piece Coordinate System

Workpiece Coordinate System Shift

Displaying and Setting the Workpiece Origin Offset Value

Wear Offset Manipulations

3. GETTING MORE FROM G CODES

Introduction to G Code Systems (A Type, B Type or C Type)

Grouping of One Shot and Modal G Codes

Difference Between Constant Lead and Variable Lead Threading

Straight Thread Cutting Using G32 Or G33

Taper Thread Cutting Using G32 Or G33

Taper Threading Cycle (G92)

Variable Lead Threading (G34)

Cutting Multi Start Threads

Oil Groove Shape Cutting

Multiple threading cycle (G76)

End Face Peck Drilling Cycle (G74)

Front Face Rigid Tapping Cycle (G84)

4.CREATING PROFILES WITH ACCURACY

Direct Drawing Dimensions Programming

Incremental Mode Programming

Multiple Repetitive Cycles

Tool Nose Radius Compensation Introduction

Practical Applications Of G40, G41 And G42

5. TURNING CALCULATIONS

The Purpose of Toolpath Calculations

Facing and Turning Calculations

Trigonometric Relations

Drilling Calculations

Tool Nose Radius

Using TNRC

Incorporating TNR Calculations

Chamfer with TNRC

Chamfer Without TNRC

Arc Programming Methods

Full Arc with TNRC

Programming an Arc Motion

Calculating a Radius Without TNRC

Calculating Leading Edges Without TNRC

Partial Arc with TNRC

Finding the Arc Center Coordinates

Finding the Partial Arc Endpoints

6. SCREW THREADS AND THREADED FASTNERS

ISO, British And American Standards

Conventional Representation Of Threads

How Screw Threads Are Designated

Screw Thread Tolerances Introduction

Designation Of ISO Metric Thread Tolerance

Designation Of ISO Inch Thread Tolerance

ISO Screw Threads Tolerances Position And Grades

7. TOOLINGS AND INSERTS SELECTION

Insert Materials

Grade Of ISO Classification Of Material

Insert Designation System

Inserts Used For Aluminium

Tool Holder Designation System

Boring Bar Designation System

Threading Inserts And Toolings

Thread Insert designation System

Threading Tool Designation System

Thread Cutting Methods

Grooving And Parting Inserts

Blade And Holder Designation System

8. QUALITY AND TESTING

Measuring And Gauging Instruments

Measuring Procedure Introduction

Direct, Indirect And Comparative Measurements

Gauges And Their Application

Standard Gauges And Limit Gauges

Use Of Vernier, Dial And Digital Calipers

Types And Use Of Micrometers

Use Of Height Gauge

Use Of Dial And Digital Indicator

Dial Test Indicator

Use Of Bore Gauges

Setting Rings

Use Of Telescopic Gauges

Protractors Simple, Digital And Universal

Feeler Gauge

Thread Pitch Gauge

Radius Gauge

Electronic Radius Gauge

Inside And Outside Caliper

Centre Indicator

WHO SHOULD ATTEND

CNC Machine Setters

CNC Programmers

CAD/CAM Engineers

Production Engineers

CNC Machine Maintenance Engineers

Industrial Automation Engineers

Machine Manufacturers

Manufacturing Engineers

PREREQUISITES

CNC Turning Programming And Operating : Fanuc Entry Level(Course Code : CNC1501)

CNC Turning Programming And Operating : Siemens Entry Level(Course Code : CNC1503)

ALLIED COURSES

CNC Milling Programming And Operating : Fanuc Entry Level(Course Code : CNC1502)

CNC Milling Programming And Operating : Siemens Entry Level(Course Code : CNC1504)

CNC Custom Macro Programming : Custom Programmer(Course Code : CNC1506)

UG NX – CAD/CAM

SolidWORKS + SolidCAM

DelCAM PowerMill / FeatureCAM

CNC Milling

Turning CAM

Milling CAM

More Courses:

COURSE NAME

CNC TURNING OPERATING AND PROGRAMMING > SINUMERIK CONTROL

CONTROLLER - INDUSTRIAL SINUMERIK CNC CONTROL

COURSE LEVEL - INTRODUCTORY

COURSE OVERVIEW

With CNC turning and Operating training on Sinumerik Control, the user learns to operate the CNC Turning machine and execute the programs.

The training program is divided into 3 sections.

Section 1 contains information about the theoretical concept of Sinumerik programming codes.

In section 2 the Sinumerik control panel keys and operating modes are introduced with the help of simulation software.

It enables them to learn how to use the workshop-compatible Sinumerik CNC control.

Finally, in section 3, the users can do the hands on practice in CNC machines.

DURATION - 10 Days

COURSE CO-ORDINATOR

Mr. Dharmender Singh (B.E. Mech., M.E. Production)

Mr. Dharmendra Patel (B.Tech.Production)

COURSE TOPICS

1. INTRODUCTION

What is a CNC control?

How SINUMERIK CNC control is different from other CNC controls

Introduction to SINUMERIK CNC control screen layout

Sinumerik Program file extentions

Explanation of Coordinate system

Meanings of WCS, MCS and reference point

Right hand rule for Lathe Axis designation

Fundamentals of 2 Axis, 3 axis and 5 axis CNC Turning machine

Fundamental Difference between Turning and TurnMill

Advantage of dual spindle CNC Turning

Description of Operating Modes

Manual control modes : JOG/HANDLE/MDA Modes

Description of working in AUTO Mode

Description of feed override and spindle speed override

2.· CNC TURNING MACHINE SETUP AND MACHINING OPERATIONS

What is a Lathe?

How the Lathe Machine Works

Machine Components and Their Locations

List of CNC Turning Machine Operations

Tool selection Criterion

Tool Holding In Tool Turret

Nomenclature of Tools and Inserts

Work Holding Methods

Introduction of Fixtures

What is MCS and WCS in CNC Terms

Programming and Setting the Job Zero

Demonstration of Different Machine Components on CNC Lathe

Introduction to Simulation Software

3. PART PROGRAM CREATION AND EDITING METHODS

Explanation of Elements of Program Header

Program Units Selection

Tool Selection and Calling Offsets

Spindle Speed Selection and Direction of Rotation

Concept of Constant RPM (G97) and Constant Surface Speed (G96)

Setting The Cutting Feed Rate (G94 and G95)

Absolute Programming (G90)

Incremental Programming (G91)

Linear Tool Path Programming (G00 and G01)

Simple Programs for Facing and Chamfering

Simple Programs for Step Turning and Taper Turning

Circular Tool Path Programming (G02 and G03)

Creating Fillets and Rounds on Workpiece

Tapers/Angles command - ANG =

Incorporating Optional Stop and Program Skip Commands

Necessary Elements of Program Footer

Different Methods / Codes to End a Program

Computer Simulation Practicals to Use a Machine Panel

Program Creation, Editing and Verification

Machining Practice on Real Time Industrial CNC Turning Machine

4.ADVANCE PROGRAMMING TECHNIQUES FOR TURNING JOBS

Outside Turning - Cycle 95

Facing - Cycle 95

Grooving Cycle – Cycle 93

Undercut – Cycle 94

Machining with undercut – Cycle 95

Threading Undercut – Cycle 96

Strategy Planning For Forged and Cast Components

Criteria for Feed, Speed and Depth of Cut Selection

Introduction to Insert Grades for Hard Materials

Industry Case Studies

Industry Based Exercises and Questionnaire for Practice

Verification and Simulation of Advance Programs

Training Videos by World Class CNC Machine Manufacturers and Users

Machine Practicals for Cutting Job Using Advance Programming Codes

5.CUTTING THREADS ON CNC TURNING MACHINE

Theory Classes on Thread Profiles and Thread Nomenclature

Introduction to ISO, British and American Thread Standards

Threading Insert Types and Selection Criteria

Introduction to Thread Cutting Strategy For Accurate Profile Machining

Cutting Straight Threads

Concept of Single Start Threads

Cutting Right Hand Threads

Threading Codes G33 and Cycle 97

Chaining of Thread – Cycle 98

Thread Cutting Practicals on Simulation Software

Setting Machine for OD and ID Threading

Real Time Machining Practical on Industrial CNC Turning Machine

6.INTERNAL (ID) MACHINING OPERATIONS

Introduction to Drilling Boring and Tapping Operations

Drilling Centring Cycle : Cycle - G81

Straight Boring

Taper Boring

ID Chamfer and Rounds

Cutting Internal Grooves

Offline Practical on Desktop PC and 3D Simulation

Machining a Workpiece on Industrial CNC Turning Machine

WHO SHOULD ATTEND

X, XII Pass

Graduates / Under Graduates

ITI, Diploma and B.Tech. Students

CAD Operators

Product Designers

Machine Operators

Maintenance Engineers

Production Engineers

PREREQUISITES - None

ALLIED COURSES

Machine Drawing And Blue Print Reading (Course Code : EG1503)

AutoCAD Essentials (Course Code : ACAD1501)